![]() Tel:+86 0532 89922862

Tel:+86 0532 89922862

![]() Email: sales@seakongmarine.com

Email: sales@seakongmarine.com

Product Details

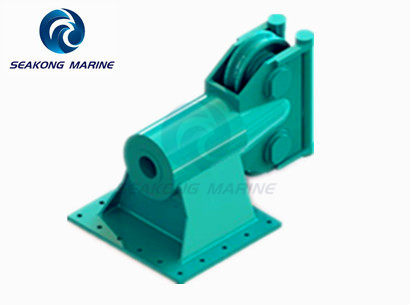

Dockside Bollards

The dockside bollards ( also known as Jetty Bollards, Pier Bitts, Jetty Bitts, Mooring Cleats, Wharf Bitts,Dock Bollards, Terminal Bollards etc )are used for mooring application when the vessels berth,our all Dockside Bollards are manufactured from high quality cast steel or cast iron.

We supply a wide range of Dockside Bollards from SWL10ton to 300ton.

Our all Dockside Bollards are strictly quenched and tempered to ensure good performance such as ductility,toughness,impact and fatigue properties, if without this quench and tempering process,the toughness will be reduced,will have great potential risk !

After heat treatment, charpy impact inspections are proceeded for each heat number castings to check the material toughness at required temperature,-60 ℃ impact inspection is available.,this is for harsh or heavy cold weather applications.

If requested at the time of order,Dockside Bollards can be furnished proof tested with certificates or only approve design calculations to save your purchase cost.

All Bollards are finished to sand blasting Sa 2.5 to enhance the paint adhesion and reduce wear. Normally, the coating system is 3 players, the Paint Brand and Colour and Dry Film Thickness on request. Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments are available.

We have developed many series these years, such as Trelleborg Series, Maritime Series,Fendercare Series.

MAIN FEATURES

· Manufactured from high quality cast steel or cast iron as sand casting production progress

· Precision casting production progress on request ,higher cost than sand casting but better performance

· SWL range: 10T~300T

· Ultralow temperature material is available

· Design calculation can be supplied when order

· 8.8 grade or 10.9 grade anchor bolts on request

· Proof load test certificate on request

· Sand blasting to Sa 2.5 or high level is available

· 3 layers coating system, Paint Brand and Colour and Dry Film Thickness can be specified

· Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments for increasing anticorrosion time are available

· CCS,BV,RINA and 3.2 material certifications are available,ABS,LR,DNV inspection report on request

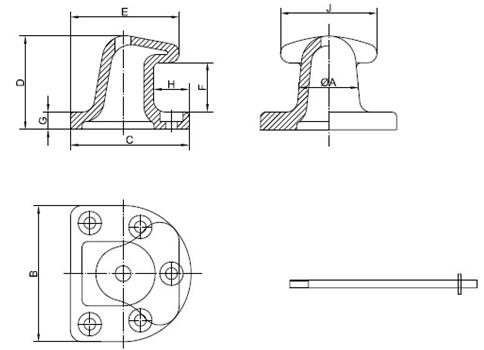

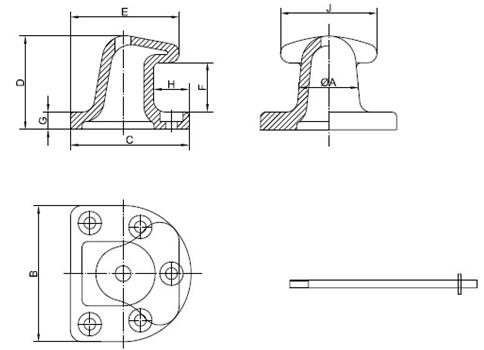

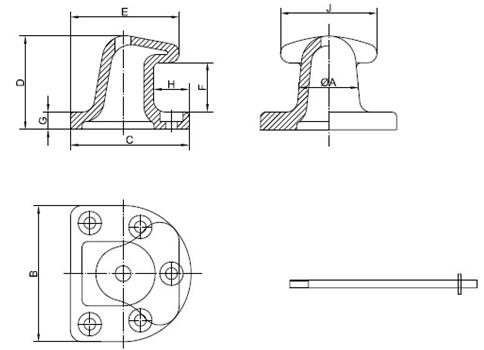

Tee Head Bollard

The dockside bollards ( also known as Jetty Bollards, Pier Bitts, Jetty Bitts, Mooring Cleats, Wharf Bitts,Dock Bollards, Terminal Bollards etc )are used for mooring application when the vessels berth,our all Dockside Bollards are manufactured from high quality cast steel or cast iron.

We supply a wide range of Dockside Bollards from SWL10ton to 300ton.

Our all Dockside Bollards are strictly quenched and tempered to ensure good performance such as ductility,toughness,impact and fatigue properties, if without this quench and tempering process,the toughness will be reduced,will have great potential risk !

After heat treatment, charpy impact inspections are proceeded for each heat number castings to check the material toughness at required temperature,-60 ℃ impact inspection is available.,this is for harsh or heavy cold weather applications.

If requested at the time of order,Dockside Bollards can be furnished proof tested with certificates or only approve design calculations to save your purchase cost.

All Bollards are finished to sand blasting Sa 2.5 to enhance the paint adhesion and reduce wear. Normally, the coating system is 3 players, the Paint Brand and Colour and Dry Film Thickness on request. Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments are available.

We have developed many series these years, such as Trelleborg Series, Maritime Series,Fendercare Series.

MAIN FEATURES

· Manufactured from high quality cast steel or cast iron as sand casting production progress

· Precision casting production progress on request ,higher cost than sand casting but better performance

· SWL range: 10T~300T

· Ultralow temperature material is available

· Design calculation can be supplied when order

· 8.8 grade or 10.9 grade anchor bolts on request

· Proof load test certificate on request

· Sand blasting to Sa 2.5 or high level is available

· 3 layers coating system, Paint Brand and Colour and Dry Film Thickness can be specified

· Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments for increasing anticorrosion time are available

· CCS,BV,RINA and 3.2 material certifications are available,ABS,LR,DNV inspection report on request

Tee Head Bollard

| Type (ton) | Dimensions(mm) | Bolt | |||||||||

| A | B | C | D | E | F | G | H | J | No. | Dia. | |

| 10 | 157 | 350 | 305 | 241 | 286 | 127 | 45 | 91 | 248 | 5 | 24 |

| 15 | 172 | 400 | 350 | 275 | 330 | 135 | 51 | 105 | 300 | 5 | 24 |

| 20 | 190 | 483 | 410 | 290 | 360 | 145 | 50 | 125 | 360 | 5 | 24 |

| 30 | 250 | 600 | 540 | 380 | 476 | 190 | 65 | 155 | 460 | 5 | 30 |

| 50 | 300 | 800 | 650 | 480 | 570 | 245 | 80 | 206 | 600 | 5 | 36 |

| 60 | 300 | 800 | 650 | 490 | 570 | 245 | 90 | 206 | 600 | 5 | 36 |

| 75 | 343 | 800 | 720 | 510 | 620 | 260 | 90 | 222 | 650 | 6 | 48 |

| 100 | 374 | 1000 | 813 | 600 | 710 | 306 | 100 | 265 | 750 | 7 | 48 |

| 125 | 376 | 1000 | 813 | 600 | 710 | 306 | 100 | 265 | 750 | 7 | 48 |

| 150 | 430 | 1080 | 900 | 670 | 830 | 350 | 110 | 283 | 800 | 7 | 48 |

| 200 | 460 | 1080 | 930 | 685 | 848 | 320 | 125 | 287 | 830 | 7 | 56 |

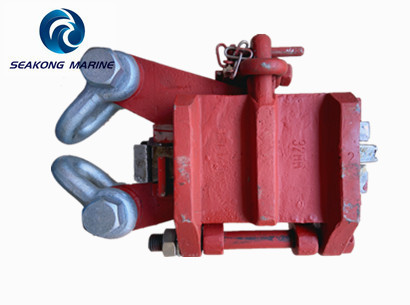

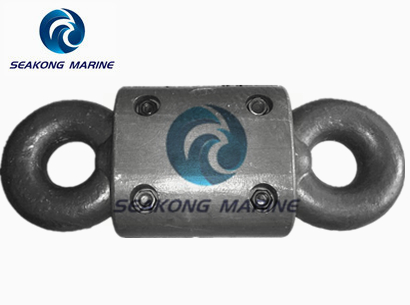

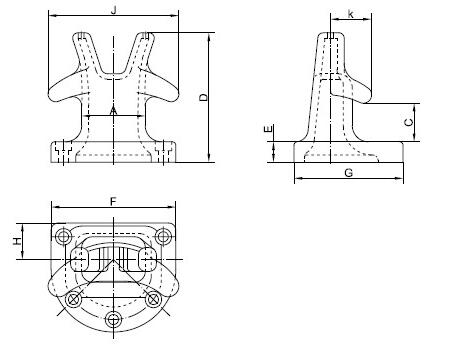

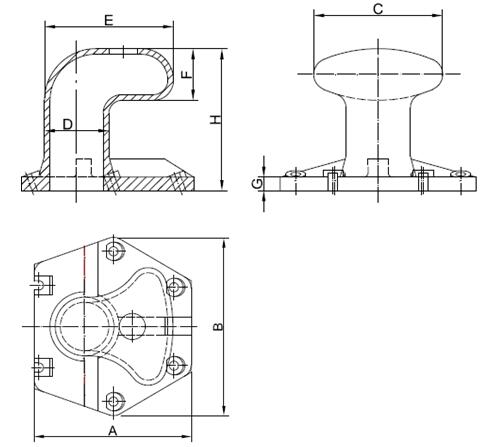

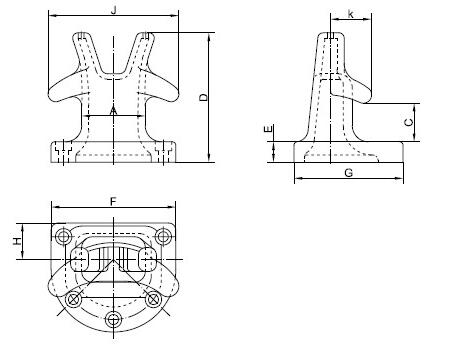

Twin Head Bollard

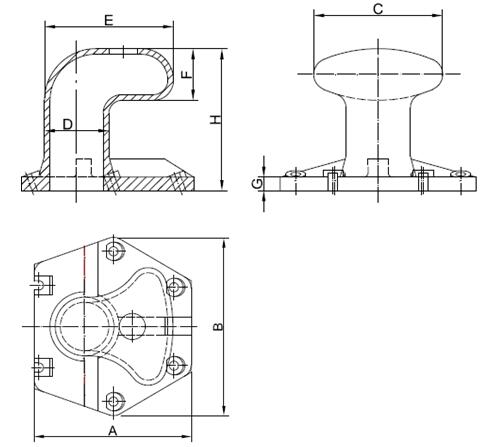

BT Type Dockside Bollard

| Type (ton) | Dimensions(mm) | Bolt | ||||||||||

| A | B | C | D | E | F | G | H | J | K | No. | Dia. | |

| 20 | 203 | 203 | 140 | 476 | 70 | 483 | 406 | 165 | 407 | 165 | 5 | 24 |

| 30 | 254 | 254 | 152 | 533 | 76 | 610 | 572 | 267 | 508 | 184 | 6 | 24 |

| 40 | 305 | 305 | 152 | 617 | 127 | 610 | 610 | 305 | 610 | 210 | 4 | 36 |

| 50/60 | 317 | 298 | 178 | 597 | 83 | 762 | 660 | 279 | 559 | 229 | 7 | 30 |

| 75 | 355 | 355 | 191 | 743 | 95 | 851 | 724 | 305 | 761 | 241 | 7 | 36 |

| 100 | 356 | 356 | 202 | 774 | 114 | 965 | 838 | 356 | 762 | 242 | 7 | 48 |

| 150 | 432 | 432 | 254 | 851 | 114 | 1016 | 914 | 381 | 838 | 278 | 7 | 48 |

| 200 | 432 | 432 | 254 | 857 | 120 | 1016 | 914 | 381 | 838 | 278 | 7 | 5 |

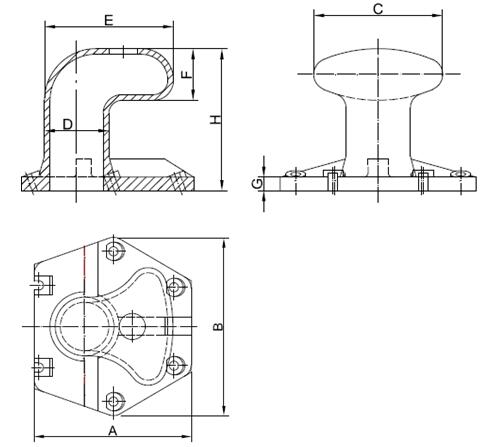

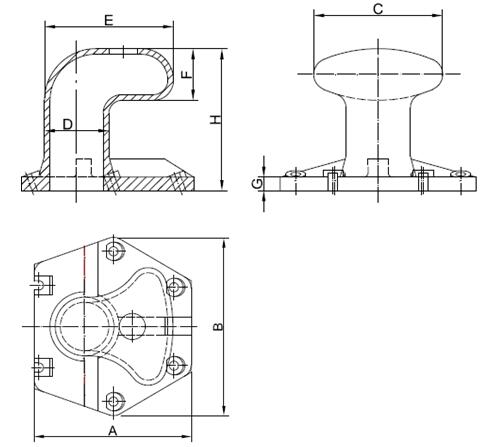

BT Type Dockside Bollard

|

Nominal Size (ton) |

A | B | C | D | E | F | G | H | No. of bolts |

Pull Load (ton) |

| 50 | 840 | 934 | 700 | 350 | 700 | 280 | 65 | 780 | 6xM48 | 50 |

| 75 | 1067 | 1224 | 750 | 400 | 750 | 300 | 75 | 885 | 6xM52 | 75 |

| 100 | 1200 | 1350 | 900 | 450 | 900 | 380 | 80 | 1005 | 6xM64 | 100 |

| 150 | 1480 | 1480 | 935 | 550 | 935 | 439 | 110 | 1200 | 8xM64 | 150 |

Contact Us Now

Product Details

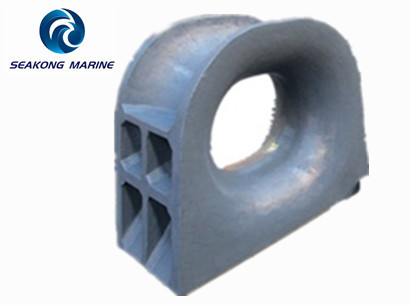

Dockside Bollards

The dockside bollards ( also known as Jetty Bollards, Pier Bitts, Jetty Bitts, Mooring Cleats, Wharf Bitts,Dock Bollards, Terminal Bollards etc )are used for mooring application when the vessels berth,our all Dockside Bollards are manufactured from high quality cast steel or cast iron.

We supply a wide range of Dockside Bollards from SWL10ton to 300ton.

Our all Dockside Bollards are strictly quenched and tempered to ensure good performance such as ductility,toughness,impact and fatigue properties, if without this quench and tempering process,the toughness will be reduced,will have great potential risk !

After heat treatment, charpy impact inspections are proceeded for each heat number castings to check the material toughness at required temperature,-60 ℃ impact inspection is available.,this is for harsh or heavy cold weather applications.

If requested at the time of order,Dockside Bollards can be furnished proof tested with certificates or only approve design calculations to save your purchase cost.

All Bollards are finished to sand blasting Sa 2.5 to enhance the paint adhesion and reduce wear. Normally, the coating system is 3 players, the Paint Brand and Colour and Dry Film Thickness on request. Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments are available.

We have developed many series these years, such as Trelleborg Series, Maritime Series,Fendercare Series.

MAIN FEATURES

· Manufactured from high quality cast steel or cast iron as sand casting production progress

· Precision casting production progress on request ,higher cost than sand casting but better performance

· SWL range: 10T~300T

· Ultralow temperature material is available

· Design calculation can be supplied when order

· 8.8 grade or 10.9 grade anchor bolts on request

· Proof load test certificate on request

· Sand blasting to Sa 2.5 or high level is available

· 3 layers coating system, Paint Brand and Colour and Dry Film Thickness can be specified

· Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments for increasing anticorrosion time are available

· CCS,BV,RINA and 3.2 material certifications are available,ABS,LR,DNV inspection report on request

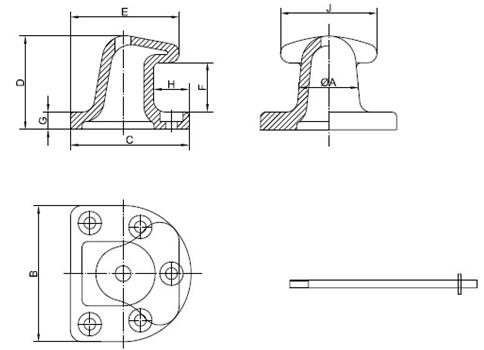

Tee Head Bollard

The dockside bollards ( also known as Jetty Bollards, Pier Bitts, Jetty Bitts, Mooring Cleats, Wharf Bitts,Dock Bollards, Terminal Bollards etc )are used for mooring application when the vessels berth,our all Dockside Bollards are manufactured from high quality cast steel or cast iron.

We supply a wide range of Dockside Bollards from SWL10ton to 300ton.

Our all Dockside Bollards are strictly quenched and tempered to ensure good performance such as ductility,toughness,impact and fatigue properties, if without this quench and tempering process,the toughness will be reduced,will have great potential risk !

After heat treatment, charpy impact inspections are proceeded for each heat number castings to check the material toughness at required temperature,-60 ℃ impact inspection is available.,this is for harsh or heavy cold weather applications.

If requested at the time of order,Dockside Bollards can be furnished proof tested with certificates or only approve design calculations to save your purchase cost.

All Bollards are finished to sand blasting Sa 2.5 to enhance the paint adhesion and reduce wear. Normally, the coating system is 3 players, the Paint Brand and Colour and Dry Film Thickness on request. Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments are available.

We have developed many series these years, such as Trelleborg Series, Maritime Series,Fendercare Series.

MAIN FEATURES

· Manufactured from high quality cast steel or cast iron as sand casting production progress

· Precision casting production progress on request ,higher cost than sand casting but better performance

· SWL range: 10T~300T

· Ultralow temperature material is available

· Design calculation can be supplied when order

· 8.8 grade or 10.9 grade anchor bolts on request

· Proof load test certificate on request

· Sand blasting to Sa 2.5 or high level is available

· 3 layers coating system, Paint Brand and Colour and Dry Film Thickness can be specified

· Electrostatic Spraying or Gavanized or Dacromet etc high-level surface treatments for increasing anticorrosion time are available

· CCS,BV,RINA and 3.2 material certifications are available,ABS,LR,DNV inspection report on request

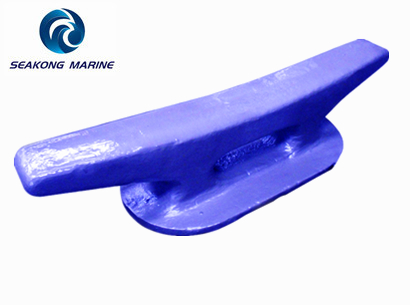

Tee Head Bollard

| Type (ton) | Dimensions(mm) | Bolt | |||||||||

| A | B | C | D | E | F | G | H | J | No. | Dia. | |

| 10 | 157 | 350 | 305 | 241 | 286 | 127 | 45 | 91 | 248 | 5 | 24 |

| 15 | 172 | 400 | 350 | 275 | 330 | 135 | 51 | 105 | 300 | 5 | 24 |

| 20 | 190 | 483 | 410 | 290 | 360 | 145 | 50 | 125 | 360 | 5 | 24 |

| 30 | 250 | 600 | 540 | 380 | 476 | 190 | 65 | 155 | 460 | 5 | 30 |

| 50 | 300 | 800 | 650 | 480 | 570 | 245 | 80 | 206 | 600 | 5 | 36 |

| 60 | 300 | 800 | 650 | 490 | 570 | 245 | 90 | 206 | 600 | 5 | 36 |

| 75 | 343 | 800 | 720 | 510 | 620 | 260 | 90 | 222 | 650 | 6 | 48 |

| 100 | 374 | 1000 | 813 | 600 | 710 | 306 | 100 | 265 | 750 | 7 | 48 |

| 125 | 376 | 1000 | 813 | 600 | 710 | 306 | 100 | 265 | 750 | 7 | 48 |

| 150 | 430 | 1080 | 900 | 670 | 830 | 350 | 110 | 283 | 800 | 7 | 48 |

| 200 | 460 | 1080 | 930 | 685 | 848 | 320 | 125 | 287 | 830 | 7 | 56 |

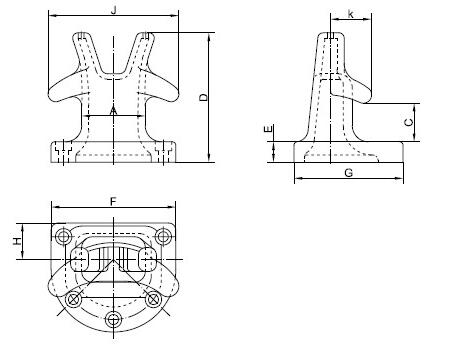

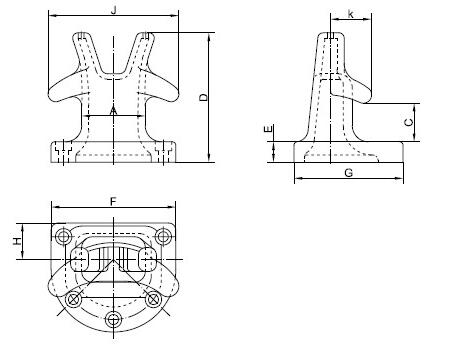

Twin Head Bollard

BT Type Dockside Bollard

| Type (ton) | Dimensions(mm) | Bolt | ||||||||||

| A | B | C | D | E | F | G | H | J | K | No. | Dia. | |

| 20 | 203 | 203 | 140 | 476 | 70 | 483 | 406 | 165 | 407 | 165 | 5 | 24 |

| 30 | 254 | 254 | 152 | 533 | 76 | 610 | 572 | 267 | 508 | 184 | 6 | 24 |

| 40 | 305 | 305 | 152 | 617 | 127 | 610 | 610 | 305 | 610 | 210 | 4 | 36 |

| 50/60 | 317 | 298 | 178 | 597 | 83 | 762 | 660 | 279 | 559 | 229 | 7 | 30 |

| 75 | 355 | 355 | 191 | 743 | 95 | 851 | 724 | 305 | 761 | 241 | 7 | 36 |

| 100 | 356 | 356 | 202 | 774 | 114 | 965 | 838 | 356 | 762 | 242 | 7 | 48 |

| 150 | 432 | 432 | 254 | 851 | 114 | 1016 | 914 | 381 | 838 | 278 | 7 | 48 |

| 200 | 432 | 432 | 254 | 857 | 120 | 1016 | 914 | 381 | 838 | 278 | 7 | 5 |

BT Type Dockside Bollard

|

Nominal Size (ton) |

A | B | C | D | E | F | G | H | No. of bolts |

Pull Load (ton) |

| 50 | 840 | 934 | 700 | 350 | 700 | 280 | 65 | 780 | 6xM48 | 50 |

| 75 | 1067 | 1224 | 750 | 400 | 750 | 300 | 75 | 885 | 6xM52 | 75 |

| 100 | 1200 | 1350 | 900 | 450 | 900 | 380 | 80 | 1005 | 6xM64 | 100 |

| 150 | 1480 | 1480 | 935 | 550 | 935 | 439 | 110 | 1200 | 8xM64 | 150 |

Contact Us Now:

-

ABOUT US

-

PRODUCT

-

NEWS

-

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

NEWS

CONTACT US

ADDRESS:No.19 Qutangxia Road, Shinan District,Qingdao City,China

TELEPHONE:+86 0532 89922862

E-MAIL:sales@seakongmarine.com

.jpg)